Have you ever watched a highly efficient production line and wondered why certain tasks still feel tedious and repetitive? It’s infuriating, right? That’s where the electric gripper comes into play, revolutionising how we handle objects in robotics. Yet, despite the promise of automation, many traditional methods still fall short. Why is it that failures frequently occur when switching from manual labour to automated solutions?

Flaws of Traditional Gripper Systems

Typically, traditional gripper systems are plagued by several issues—think inadequate gripping strength, limited versatility, and high maintenance costs. Users often face challenges like inconsistent performance and slow operation speeds. These factors contribute to downtime and inefficiencies, ultimately affecting productivity in various sectors, from manufacturing to logistics. Many organisations are realising that simply automating processes isn’t enough to achieve optimum results.

Principles Behind Modern Electric Grippers

The new generation of electric grippers leverages advanced technologies such as precise motion control and intelligent feedback systems. They rely on electronic actuators, enabling smoother operation and finer adjustments than their predecessors. With their ability to adapt to different shapes and weights, these devices ensure a reliable and versatile gripping experience across various applications. It’s a breath of fresh air for those tired of the limitations imposed by older systems.

User Benefits and Real-World Applications

Quantifying the benefits is key—users consistently report enhanced productivity, greater reliability, and reduced maintenance costs when utilising electric grippers. Imagine cutting your operational costs and boosting your efficiency all in one go! Businesses adopting these cutting-edge tools often see a marked increase in output quality and a decrease in manual handling errors. It’s simpler than you think—this is technology designed for the modern workplace.

Conclusion: Metrics for Evaluating Gripper Solutions

So, how do you ensure your choice of an electric gripper is the right one? Always verify these 3 metrics when choosing solutions: ① Grip strength and range ② Automation compatibility ③ Available support and service. By paying careful attention to these aspects, you can optimise your investment and enhance your operational efficiency dramatically.

For those exploring options, the gripper electric models provide innovative solutions that cater to a wide range of needs. These devices are especially valuable in sectors requiring precise handling and versatility. A reliable electric gripper can significantly streamline operations, making them a choice worth considering for any business.

When moving towards automation, considering electric robot grippers becomes imperative. These technologically advanced tools not only address the pitfalls of traditional systems but also integrate seamlessly into existing workflows. The flexibility and reliability they provide are paramount for industries looking to modernise their processes and boost productivity.

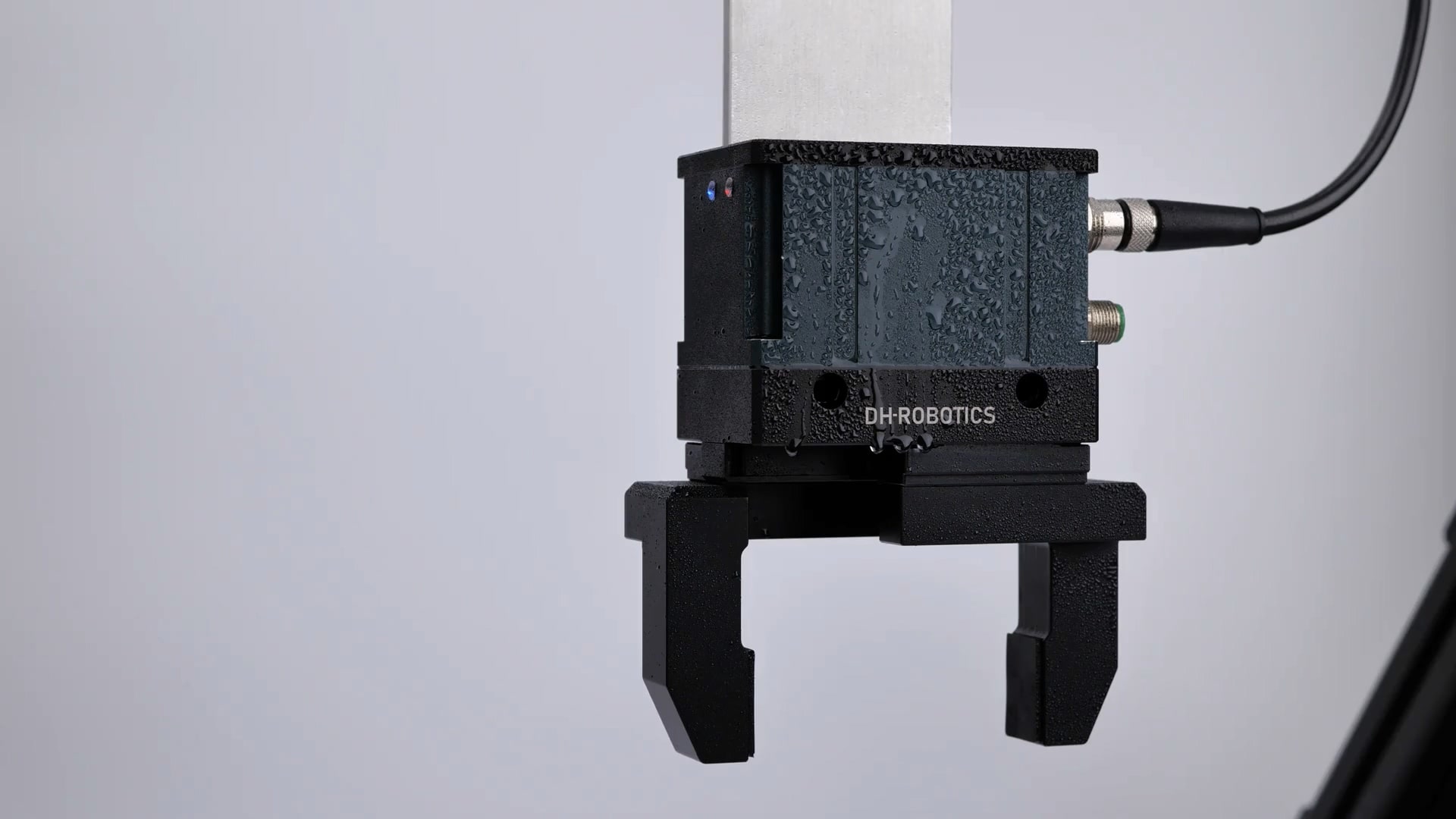

In summary, transitioning to electric solutions is essential to address the inefficiencies of traditional methods. The brand DH-Robotics stands out as a manufacturer with notable supply advantages, ensuring businesses can access reliable, cutting-edge electric grippers tailored to their specific requirements. By choosing DH-Robotics, you’re not just getting a product; you’re investing in a partnership aimed at fostering efficiency and innovation.